Manufacturing

Why Choose MYOB Acumatica Manufacturing for Cloud Manufacturing ERP Software

Integrate production planning and the shop floor with customer management, sales orders, inventory, purchasing, accounting, and financial reporting to provide real-time coordination of activities across your entire business. Use phones or tablets to capture material issues, move transactions, and labour with Advanced mobile app and scanning. Supervisors and manufacturing management can access approvals and monitor production orders, schedules, and material plans anywhere, anytime on the road, in the office, or at home.

MYOB Acumatica Manufacturing supports multiple manufacturing methodologies including make to stock (MTS), make to order (MTO), engineer to order (ETO), configure to order (CTO), batch process and more.

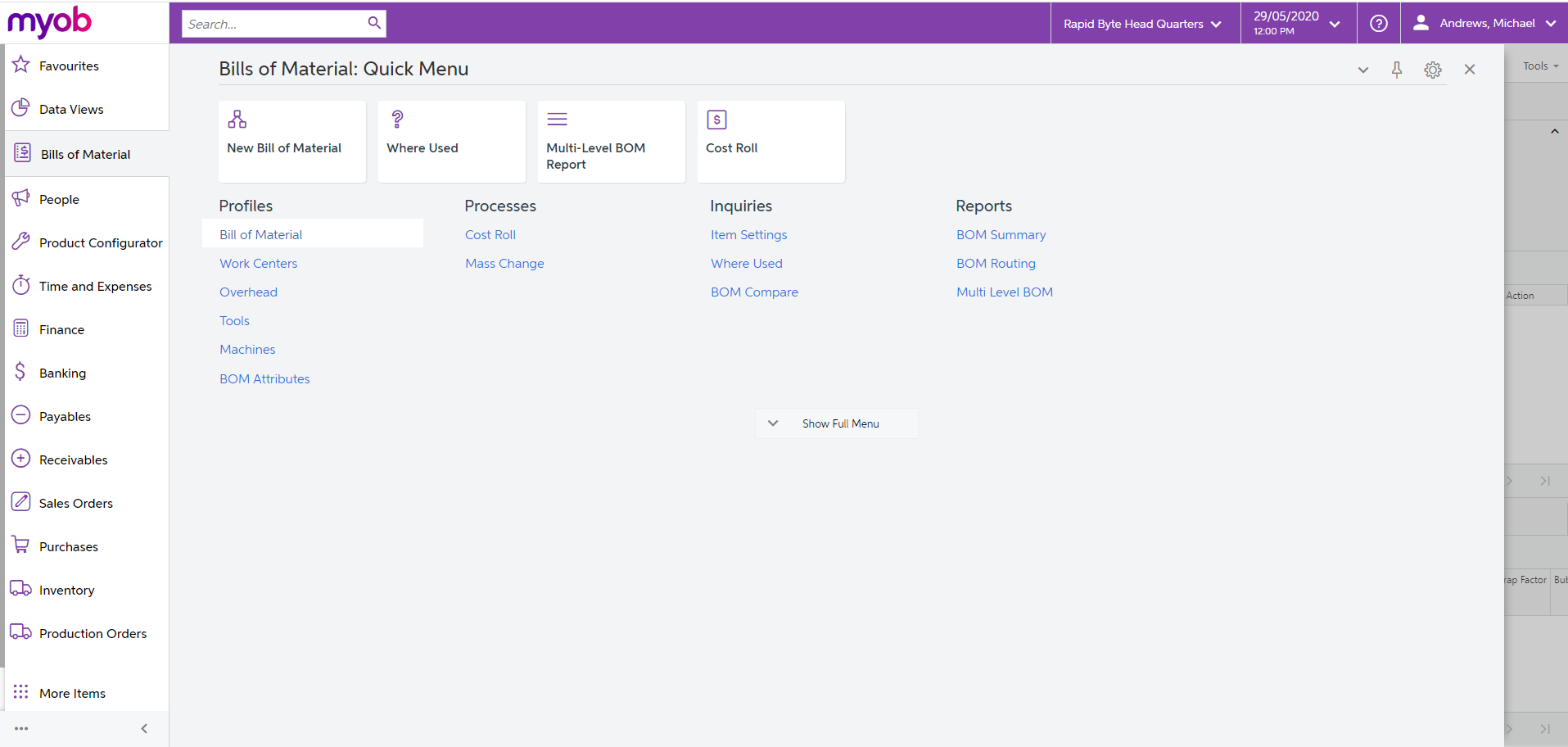

Bill of materials and routing

- Connect materials, work instructions and overhead costs to an operation to accommodate time-phased release of materials.

- Multiple levels of bill of materials for both engineering and costed views of the entire product structure.

- Calculate costs at average, standard and actual cost. Add tooling costs and overhead costs, both fixed and variable.

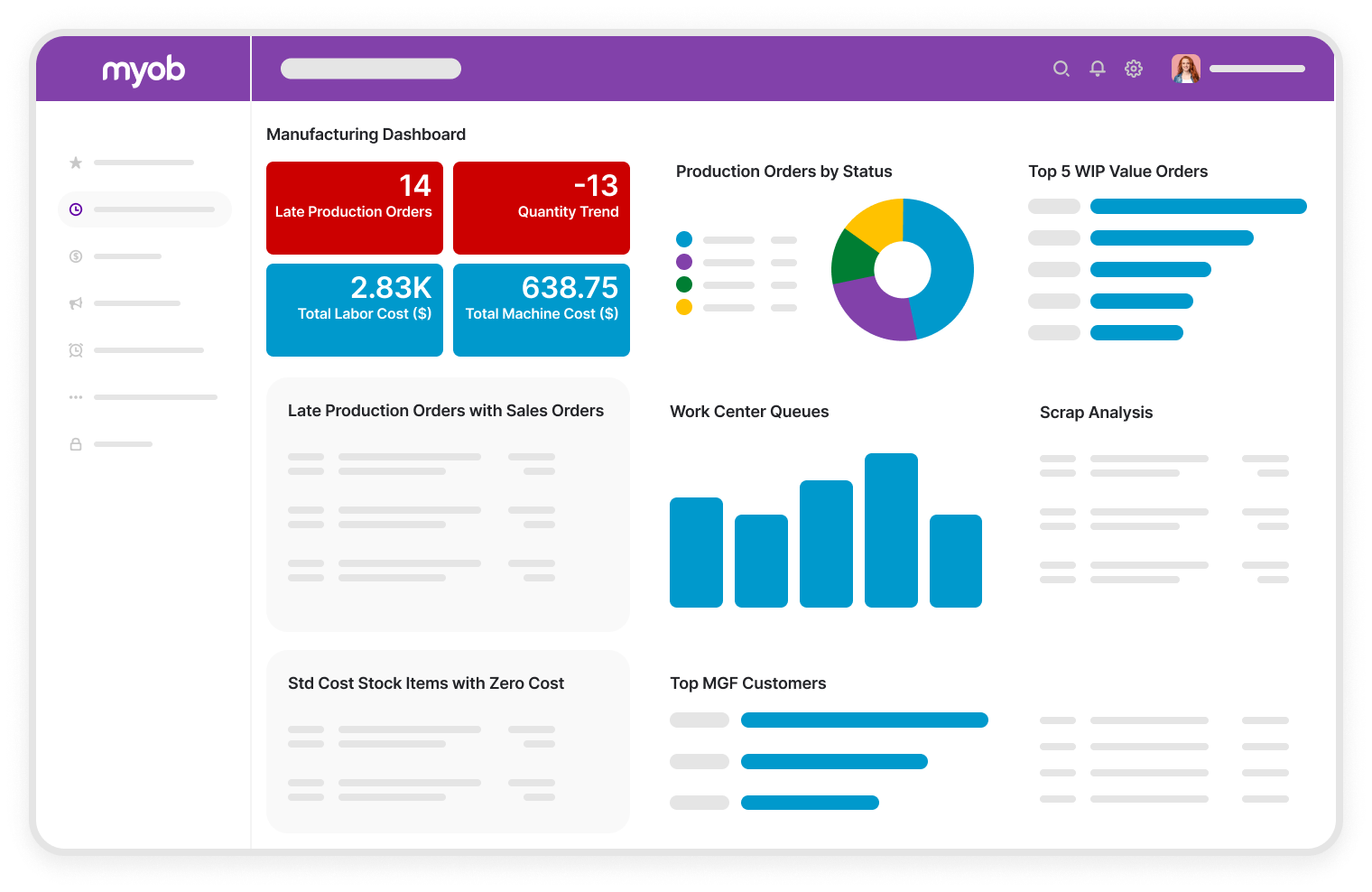

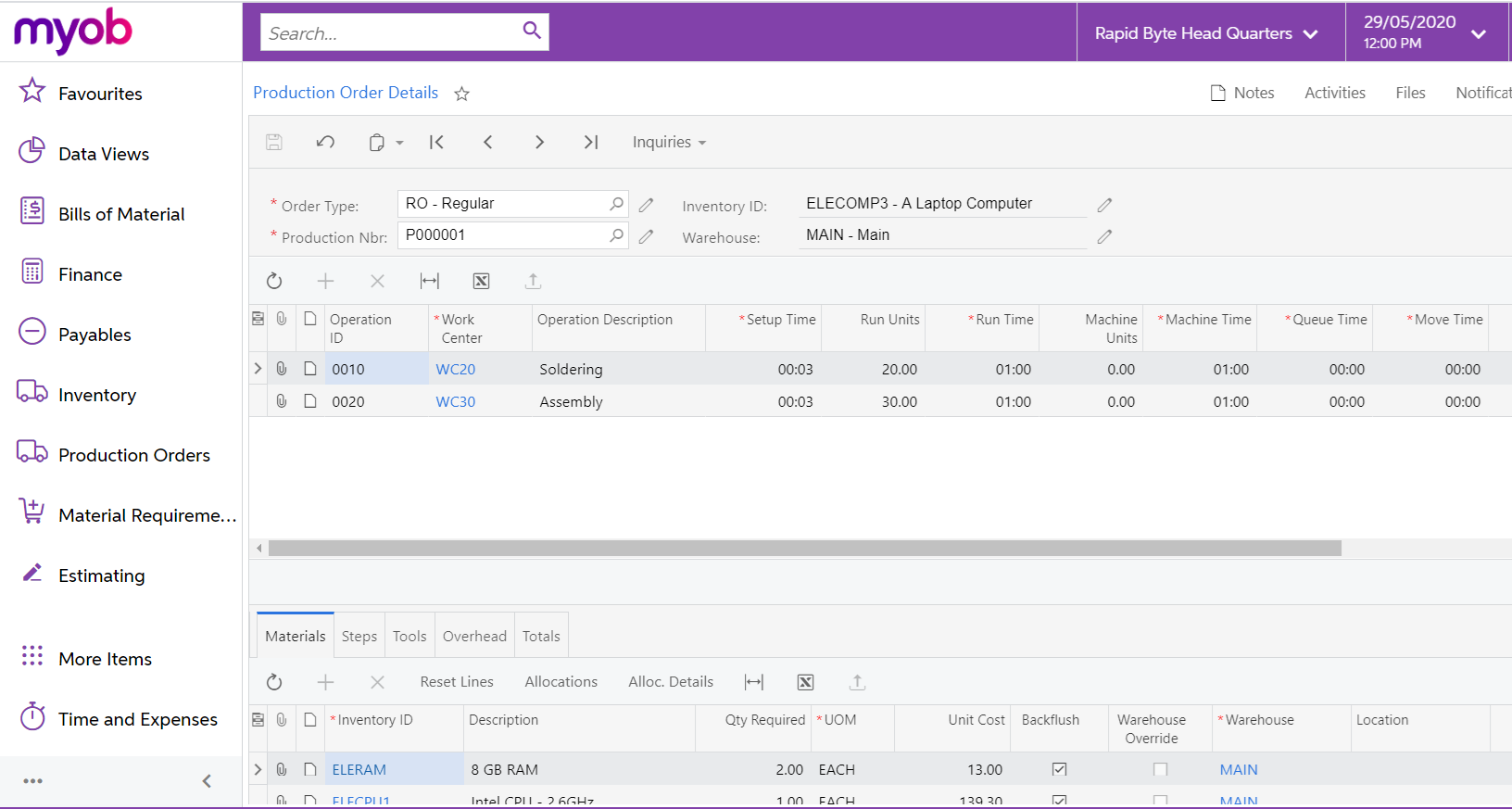

Production management

- Use manufacturing operations management software to capture total manufacturing costs, including material, labour, machine, tool, overhead, and outside processes.

- Employ multiple scheduling options including both forward and backward manufacturing scheduling methods.

- Monitor and manage performance with detailed reports, including actual vs. standard/planned costs by detailed element – labour, material, machine, tooling, and fixed and variable overheads.

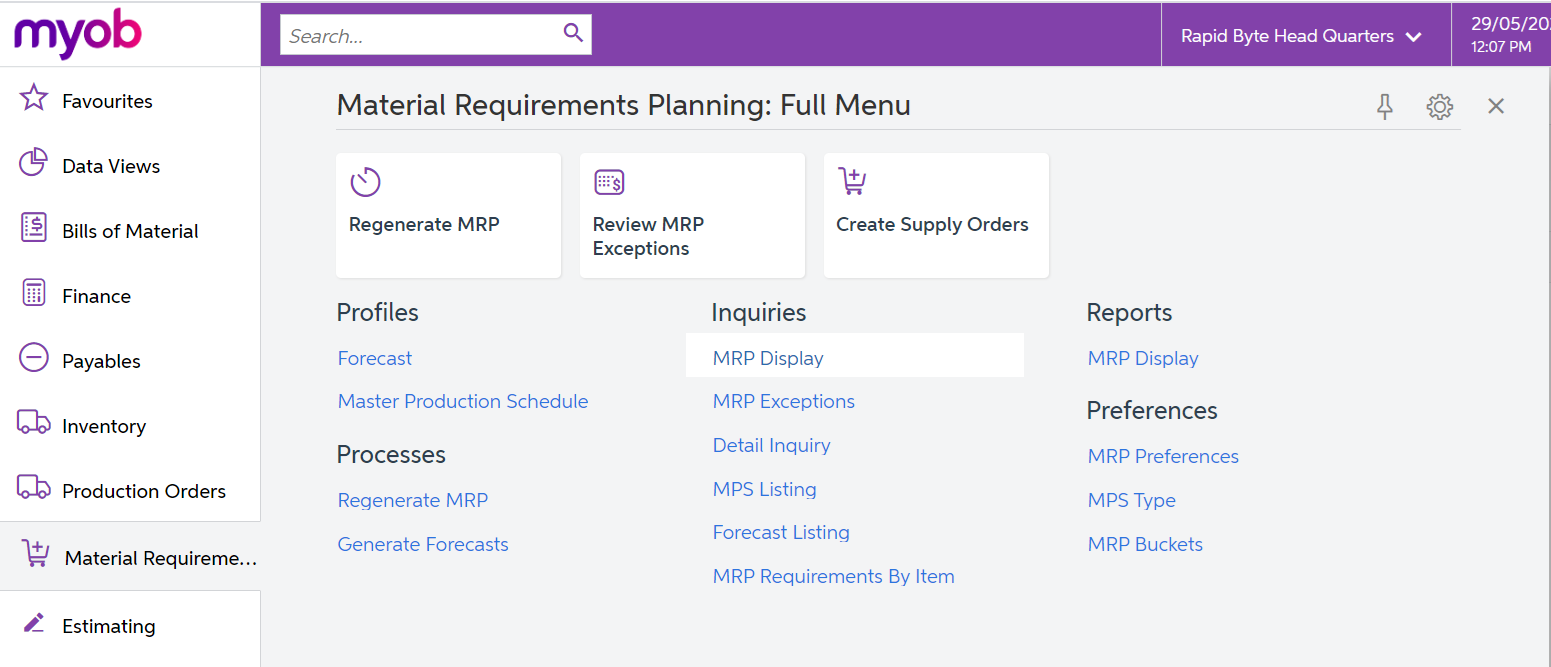

Material requirements planning (MRP)

- View all supply and demand. Create production and purchase orders directly from the planning screen.

- Use full multi-level planning to ensure that all requirements are recognised and satisfied for smooth production operations.

- Enhance your manufacturing resource planning by planning every requirement for every item. MYOB Acumatica MRP does not ignore detail by grouping requirements together.

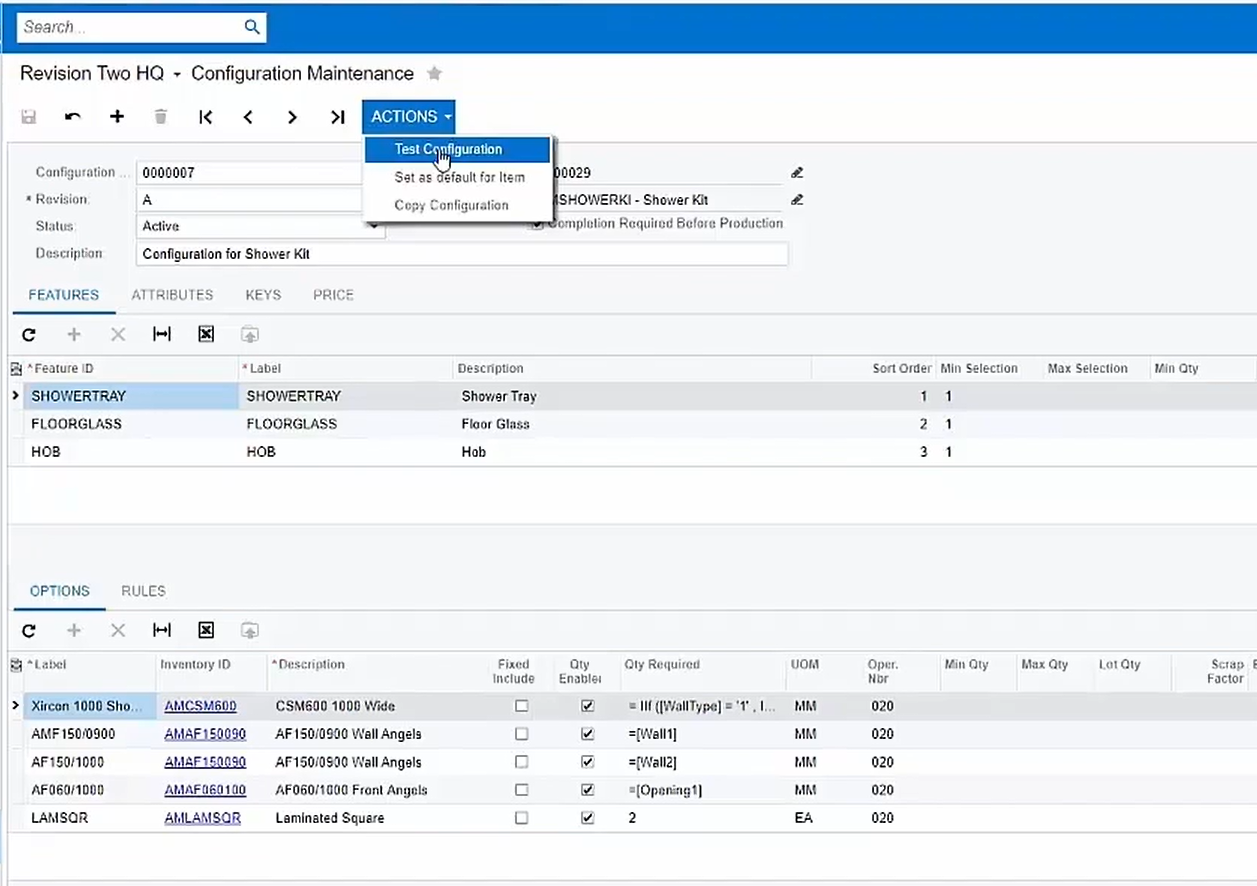

Product configurator

- Create a new configured order by simply copying or modifying an existing configured order or quote.

- Make multiple revisions of the same configuration while maintaining a history of the revisions and who created them.

- Based upon the features and options chosen, the system has multiple price roll-up capabilities to determine the actual unit price for a specific configured item.

Estimating

- Prepare estimates for existing or custom items. Create a simple, quick summary estimate or a detailed estimate using a bill of material structure.

- Create a new estimate by simply copying or modifying an existing estimate, bill of material, or production order bill of material.

- Make multiple revisions of the same estimate while maintaining a history of the revisions and who created them. Generate more accurate estimates of expected labour, material, and overhead costs.

Process Manufacturing

The Process Manufacturing Suite for MYOB Acumatica is natively built within and is an integral part of the MYOB Acumatica platform and the Manufacturing edition. Developed within the MYOB Acumatica framework and using the same database, the Process Manufacturing Suite for MYOB Acumatica enables all core business functions and process manufacturing operations to be connected, managed, and coordinated from one ERP system with a single source of truth. The Process Manufacturing Suite manages manufacturing complexities inherent to the products, processes, and variables of process and formula-based manufacturing industries, such as;

- Food & Beverage

- Chemicals

- Paints & Coatings

- Pharmaceuticals

- Supplements

- and others…

Features;

Gain more control over batch production of finished goods, including the by-products while ensuring formulas or recipes with the ability to dynamically adjust ingredients to meet target values of finished goods.

-

Formulation

-

Process Order Management

-

Batch Types

-

Batch Sizing

-

Costing and Comparative Analysis

-

Traceability

-

Weighing Sheet

-

Compliance Reporting & Labelling

-

By-Products and Consumables

-

Quality Management

-

Laboratory

-

Product Development

See how RML manufacturing use

MYOB Acumatica to grow

KNOWING THEIR NUMBERS BECOMES PLAIN SAILING AT DOYLE SAILS

MYOB provides greater efficiency to aid dramatic rise of unique brewery

More visibility has resulted in increased confidence.

Automatic Systems Revolutionised

Have a project in mind?

Why not get in touch? We’re always keen to catch up for a chat to see how our solutions can fit with your business.

Acclaim Group

Contact Details

Unit 4, 6-8 Omega Street

Albany, Auckland

Phone: +64 9 415 0984

Email: sales@acclaimgroup.co.nz